Make your lab hardware talk to your informatics software: SLAS2021 at a glance

Every year, the Society for Laboratory Automation and Screening (SLAS) brings life science professionals together to consider the ways in which lab automation will rapidly scale life science R&D and accelerate new technologies’ time to market. At this year’s SLAS2021 Digital Conference, Benchling’s Tara Lee – Product Manager for Benchling for Lab Automation – demonstrated how Benchling’s software connects instruments to informatics to transform life sciences R&D. See the full presentation below.

The Era of Automation

The life sciences industry is rapidly expanding and evolving, and lab automation is critical to that growth. As new, complex drug modalities emerge and as companies need to accelerate time to market, throughput requirements have increased, as has investment in instrumentation and robotics to bolster this acceleration.

Yet these lab automation instruments are only as powerful as the data they produce is capturable. Many conventional LIMS systems are not designed to efficiently process and analyze data from laboratory hardware.

That’s where Benchling comes in. Benchling is a cloud-based software solution that supports the full breadth of life sciences R&D processes. From design to experimentation to analysis, Benchling powers traceability and visibility for the entire R&D workflow, allowing you to optimize your processes with greater efficiency. Benchling for Lab Automation links software and hardware to help R&D organizations increase experimental scale, enhance productivity, accelerate time to milestone, improve data integrity, and access data-driven insights.

Benchling for Lab Automation integrates with automation instruments like liquid handlers and analytical instruments to generate and process input and output files. Moreover, it is interwoven with the rest of the Benchling platform to seamlessly register samples and manage inventory in real time. As a result, scientists can save more than 10 hours per experimental run.

Benchling for Lab Automation and COVID-19

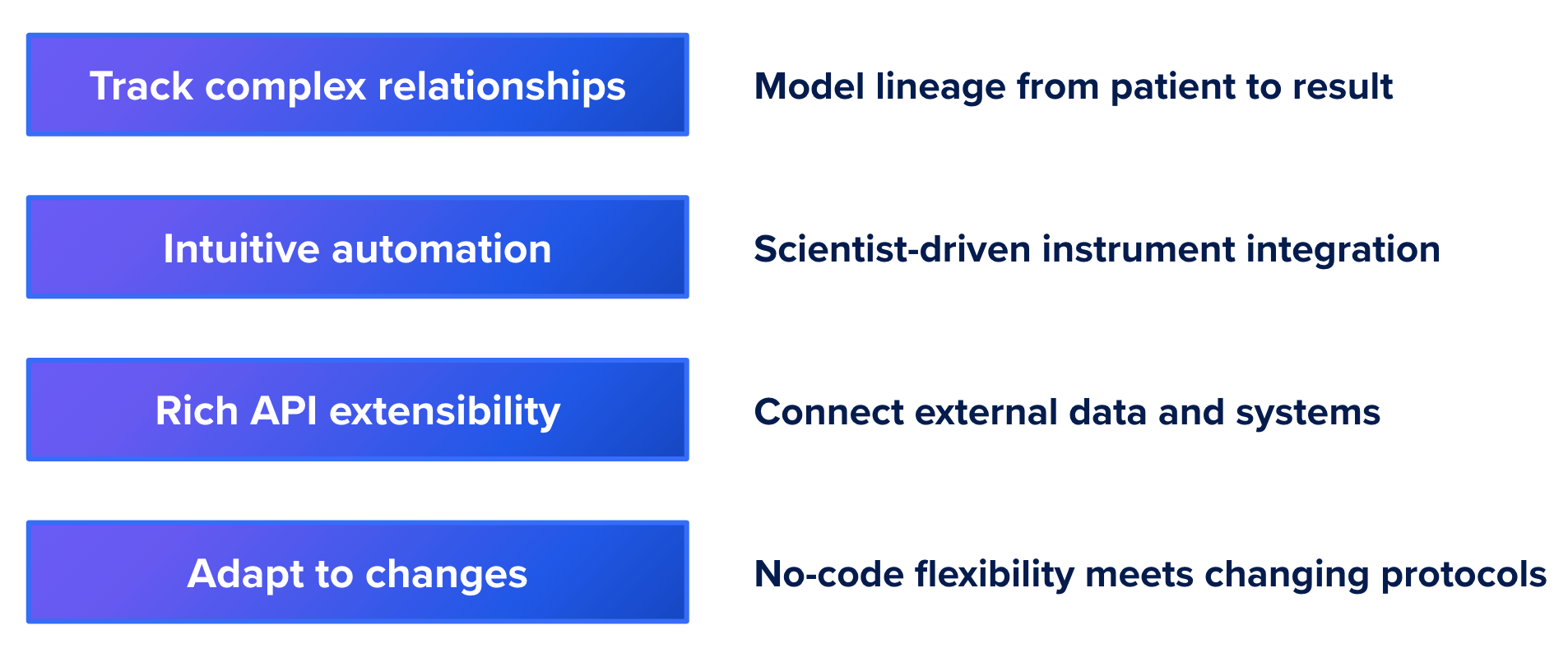

In the spring of 2020, Benchling partnered with Corteva Agriscience and Technical University of Denmark (DTU) to advance and accelerate COVID-19 testing. Benchling for Lab Automation drives key aspects of any R&D pipeline, including tracking of complex relationships, intuitive automation, rich API extensibility, and adaptability in the face of change. For COVID-19 testing at Corteva and DTU, this enabled four key capabilities: modeling lineage from patient to result, scientist-driven instrument integration, connection to external data and systems, and no-code flexibility when protocols change.

Benchling unlocks core capabilities for COVID-19 testing at DTU and Corteva Agriscience.

Watch Tara Lee’s presentation above to take a deeper dive into the capabilities of Benchling for Lab Automation and to see how Corteva and DTU leverage these capabilities to power COVID-19 testing.

Powering breakthroughs for over 1,200 biotechnology companies, from startups to Fortune 500s