The Future of Food Starts with Modern Life Science Software

Curious how Clara Foods accelerates future food R&D with the Benchling Life Sciences R&D Cloud? Check out our webinar.

The science of culturing food has made incredible strides in the last few decades. Behind this innovative push to rethink the way we grow our food, scientific teams depend on scientific technologies, like strain engineering and fermentation, that are increasingly complex and varied. However, while the science is rapidly advancing, future food scientists still find their work stymied by the tools they use to gather and analyze their data. Future food scientists often spend valuable time on clerical work that detracts from time to ideate and innovates their R&D. Three unique but interlocking teams common to future foods R&D face critical challenges in handling vast amounts of data with legacy software that has limited capabilities. These pioneers need software solutions that are purpose-built for future food science in order to fully capture their discoveries and bring their innovations from the lab to the world.

1. The Challenge for Strain Engineers: Plasmid Parts to the nth Degree

Strain engineering is a common function in cultured food labs, as well as in many industrial biotech labs. Strain engineers take a microorganism, yeast being the most common, and functionally alter its genome in a way that is both benign and beneficial. Some examples would be enabling a microorganism to produce a certain biomaterial or influencing the way it metabolizes a particular substrate.

Strain engineers have a lot to keep track of, from plasmid design to actual strain creation to strain bank management. These scientists are designing thousands of plasmids in a given workflow, and they have to track all of the relevant parts and strains as they try to keep up with that high level of throughput. And when they’re using a legacy data management system, this can be frustrating at best.

“We run hundreds of fermentations across different scales with different strains. Benchling allows us to filter and parse through it. It allows us to compare strains week to week, runs a year ago to now, and runs across different scales with ease.”

– Micah Marmorstein, Process Associate, Clara Foods

Solving the Challenge: A Comprehensive Tool for Plasmid Creation and Management

Strain engineers need a way to not only visualize and track the hundreds of thousands of parts, plasmids, and strains they work with, but to also connect all of these entities to each other and to relevant downstream experiments.

As strain engineers have become increasingly frustrated with outdated laboratory management tools, they are looking more and more for a way to unify their data and workflows. Strain engineers need a molecular biology design tool that can not only elegantly model and test plasmids in silico but also integrate the data on these entities with strains, downstream sample lots, and the rest of their experiments’ data. They need tools that let them create and track hundreds of plasmids in parallel, rather than having to painstakingly create plasmids in sequence, one at a time.

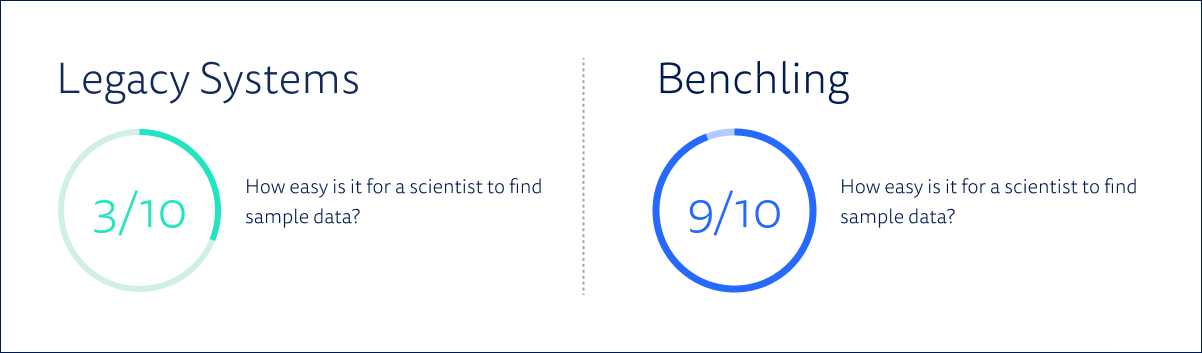

*All metrics taken from a survey of Benchling scientists

2. The Challenge for Fermentation Engineers: Disconnected Systems and Scattered Data

Where there is strain engineering, there will also be fermentation down the line. Fermentation is the fully scaled-up process of using genetically engineered microbes to produce high-value materials in massive quantities, eventually for commercial use.

Fermentation is a highly sensitive process, and it’s up to fermentation engineers to actively monitor conditions in many instruments across fermentation runs to make sure they successfully and repeatedly create the same, high-quality product. Across the field, fermentation teams still rely on outdated, legacy laboratory software systems. These systems can’t effectively capture and synthesize offline and online data, such as analyses on samples and aliquots and data from the fermentors themselves. As these scientists execute run after run, these clunky and disjointed data management systems store online data from bioreactors and fermenters separately from offline data from analytical instruments. This ultimately makes it challenging to understand strain performance.

“If you’re expecting to succeed at all, you should expect a lot of data quickly. It’s much more difficult to go back when you already have a vast amount of data. If you look at any experienced entrepreneur, many of them build systems early with the growth process in mind.”

– Max Rye, Chief Strategist, TurtleTree Labs

Solving the Challenge: Blending Online and Offline Data

For future foods labs working with fermentation, it is crucial for fermentation teams to see the big picture and small details of all fermentation runs, both individually and collectively. Fermentation teams need modern laboratory software with dual capabilities. First, their software should integrate with and automatically capture data output from instruments like bioreactors. Second, this software should also blend all in-process and time-point data in a structured way. With this type of system, fermentation engineers can analyze strain performance and optimize fermentation processes. This would eliminate the hassle of hunting down siloed data and ultimately make it easier to analyze strain performance and optimize fermentation processes.

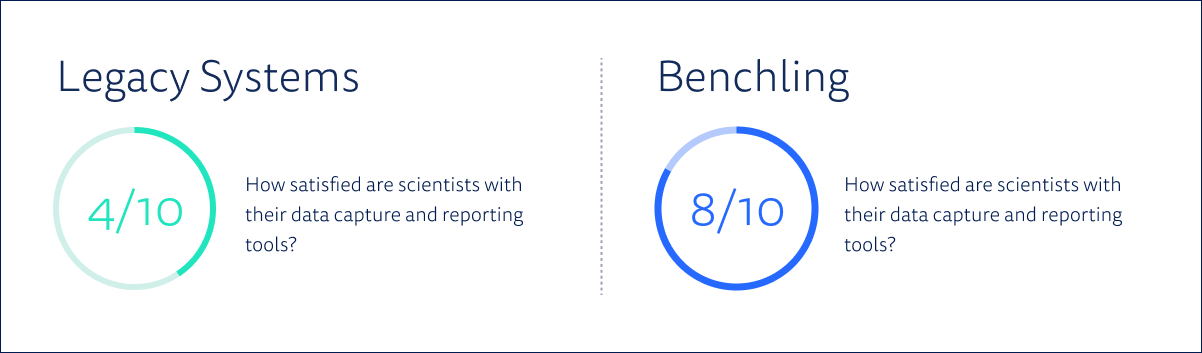

*All metrics taken from a survey of Benchling scientists

3. The Challenge for Analytical Scientists: A Lot of Data Can Mean a Long Turn-Around Time

It’s no surprise that strain engineering and fermentation are colossal operations, from the hundreds of thousands of entities that strain engineering teams work with to the highly technical process of fermentation. So when all of the data that these operations produce makes its way down the line, it’s up to analytical scientists to determine how successful an experiment was. Without a robust data management system, turning around assay results can be slow work for these analytical teams.

“We do so many experiments and a single scientist has so much to keep track of... [With Benchling,] we can ask more questions in a shorter amount of time, we can try more possibilities in a shorter amount of time.”

– Yingjie Li, Senior Engineer, Food Industry

Solving the Challenge: Automated, Error-free Data Capture

Even, and especially, when they are using outdated data management systems, analytical teams develop systematic approaches to collecting, organizing, and recording sample data. They have to in order to manage the sheer volume of data they work with. But modern analysts deserve a software system that automates and expedites these processes rather than hinders them. What’s more, modern analytical scientists need an automated method to capture assay results directly from instruments and input them, error-free, into a system of record that connects new downstream samples to upstream experimental context.

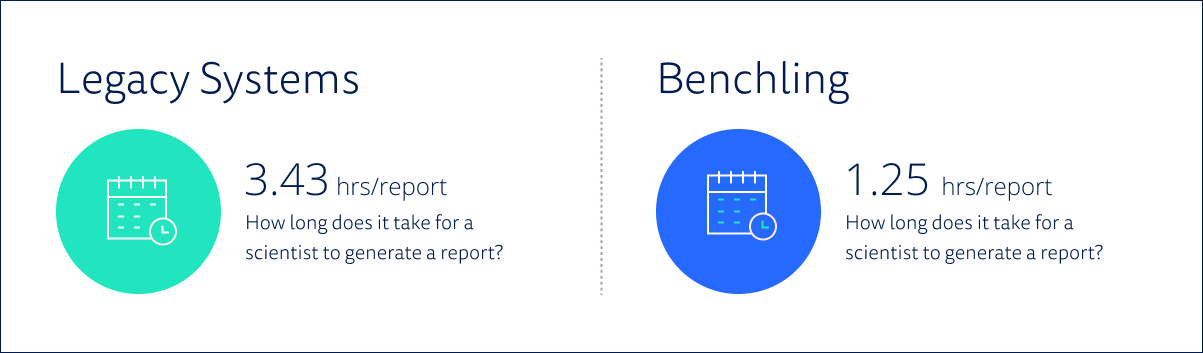

*All metrics taken from a survey of Benchling scientists

Three Unique Challenges, One Unified Solution

While there are software and hardware technologies available today that solve individual challenges listed above, a true solution needs to be universal. Future food labs need a software solution that connects the upstream strain engineer’s protocols with the fermentation engineer’s workflows and the analytical scientist’s performance testing. It’s an exciting time for future food science, and we’ve only just scratched the surface of what is possible. As future food scientists innovate the way we feed the world, Benchling's mission is to innovate the way these scientists do their work.

Learn how Benchling can accelerate your teams' future foods workflows.